Polypropylene (PP) multifilament yarn is a versatile synthetic fiber used in various industries for its strength, durability, and resistance to moisture and chemicals. In this article, we explore the manufacturing process of PP multifilament yarn, its applications, and leading manufacturers in India. Whether you're in textiles Singhal Industries - Manufacturer of Flexible Packaging Product, packaging, or industrial manufacturing, understanding the properties and uses of PP multifilament yarn is essential for informed decision-making and product sourcing.

Understanding PP Multifilament Yarn

What is PP Multifilament Yarn?

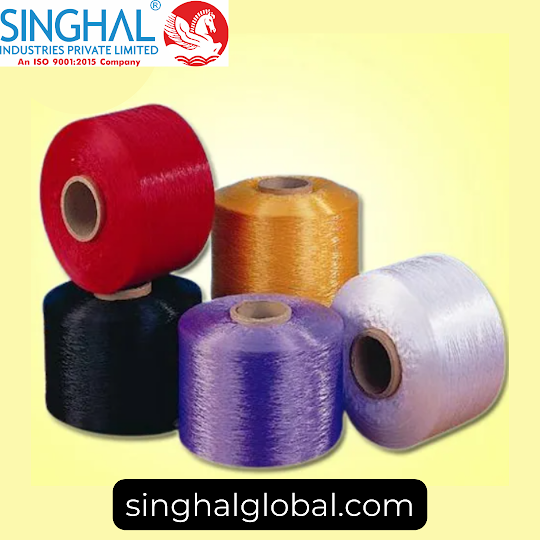

Polypropylene multifilament yarn is a type of synthetic yarn composed

of multiple continuous filaments extruded from polypropylene resin. These

filaments are twisted together to form a single yarn strand, resulting in a

strong and durable material with various applications.

Manufacturing Process

Extrusion: The manufacturing process begins with the

extrusion of polypropylene resin pellets. The pellets are melted and forced

through spinnerets to form continuous filaments of uniform thickness.

Drawing: The extruded filaments are stretched or drawn to

align the polymer chains and increase the yarn's tensile strength and

elongation properties.

Twisting: The drawn filaments are twisted together to form a

yarn strand. The twisting process imparts additional strength and stability to

the yarn.

Winding: The twisted yarn is wound onto bobbins or cones for further processing or direct use in weaving, knitting, or other textile processes.

Applications of PP Multifilament Yarn

PP multifilament yarn manufacturer finds a wide range of applications across industries, including:

Textiles: Used for weaving, knitting, and sewing

applications in the production of fabrics for apparel, home furnishings, and

technical textiles.

Industrial: Used in industrial sewing and stitching

applications for products such as bags, sacks, ropes, and nets due to its high

strength and abrasion resistance.

Geotextiles: Used in civil engineering applications such as erosion control, soil stabilization, and drainage systems due to its durability and resistance to environmental factors.

Conclusion

PP multifilament yarn manufacturer india is a versatile synthetic fiber with numerous applications across industries. From textiles and packaging to civil engineering and industrial manufacturing, PP multifilament yarn offers exceptional strength, durability, and performance. By partnering with leading manufacturers in India, businesses can access high-quality PP multifilament yarn to meet their specific needs and drive success in their respective markets.

Frequently Asked Questions (FAQs)

Q: What are the advantages of using PP multifilament yarn in

textile production?

PP multifilament yarn offers several advantages in textile

production, including high strength, durability, and resistance to moisture and

chemicals. It is also lightweight and easy to process, making it ideal for a

wide range of applications.

Q: Can PP multifilament yarn be dyed or treated for specific

applications?

Yes, PP multifilament yarn can be dyed using conventional

textile dyes or treated with additives to impart specific properties such as UV

resistance, flame retardancy, or antimicrobial properties. Customized

treatments can be applied based on the desired application and performance

requirements.

Q: Is PP multifilament yarn recyclable?

Yes, PP multifilament yarn is recyclable and can be

processed into new yarn or other plastic products through mechanical or

chemical recycling processes. Recycling PP yarn helps reduce waste and minimize

environmental impact, making it an eco-friendly choice for sustainable

manufacturing practices.

No comments:

Post a Comment